Health and safety – Guide Ti contributes to the safety of maintenance and production personnel and to better human resources management

–Control lockout and management of confined spaces in the CMMS Guide Ti

One of them is the implementation of asset-specific health and safety procedures applicable during repairs.

Better human resources management

Guide Ti helps reduce training costs and improves staff stability.

The centralization of assets and historical data helps to integrate new employees and level out a lack of training and transfer of knowledge following the unexpected departure of a key employee.

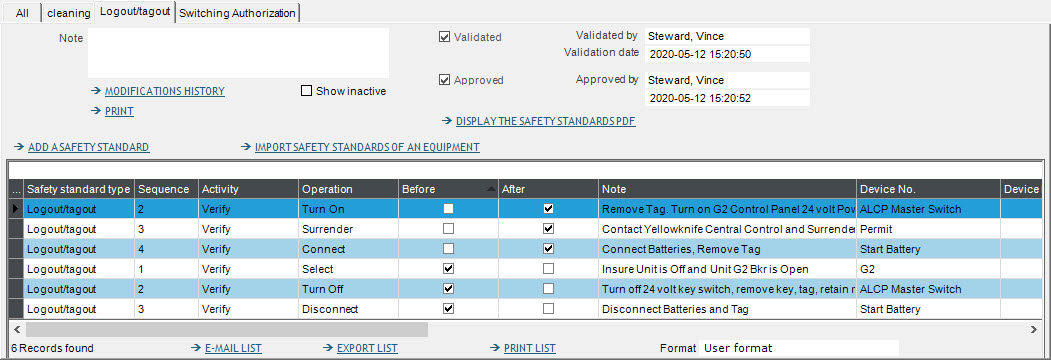

Lockout ensures that safety actions are implemented during the maintenance of the equipment

Innovations that enhance employee safety

Innovations that make a difference in health and safety in a maintenance department.

- Lockout

- Manage confined spaces

- Management and evaluation of mechanical, chemical, ergonomic and physical risk

- Calculate the risk index using mandatory questions related to the problem. These questions are based on a chart of prioritization of risks, dangers and consequences.

- Potential consequences

- Frequency

- Exposure

- Probability

- Automatic registration of security actions on WOs

Guide Ti makes it possible to assess the risk of each work order

Here are interesting features:

- History of change of standards

- Access to equipment history to facilitate the arrival and safety of new employees

- Presence of procedures by assets

Guide Ti is a Computerized Maintenance Management Software – CMMS

The CMMS Maintenance Software Guide Ti helps you manage your assets, work orders, plan and schedule both urgent repairs and preventative tasks, manage spare parts procurement and create detailed reports. It helps to manage your maintenance budget and control your expenses.

Guide Ti, our complete CMMS, enables you to:

- Reduce planner / Technician ratio

- Integrate CBM results in your CMMS

- Improve Wrench Time

- Get Real Time Precise Data

- Optimize Uptime

- Do More with Fewer Resources

- Co-ordinate with Other Department

- Co-ordinate Many Teams and Trades

Contact us for a demo and see by yourself what Guide Ti can do for you and your maintenance department!

Email: Click here to send an email

Phone: 418-626-2503

Toll-free: 1 877-424-2503